Page 45 - #46 English

P. 45

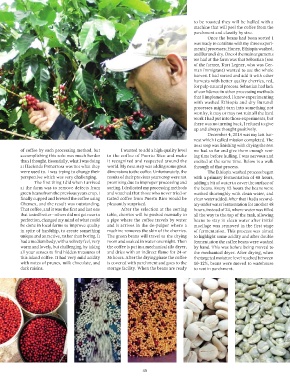

to be roasted they will be hulled with a

machine that will peel the coffee from the

parchment and classify by size.

Once the beans had been sorted I

was ready to continue with my three experi-

mental processes; Honey, Ethiopia washed,

and Burundi dry. One of the main arguments

we had at the farm was that Sebastian (son

of the farmer, Kurt Legner, who was Ger-

man immigrant) wanted to use the whole

harvest I had sorted and add it with other

harvests with better quality cherries, red,

for pulp-natural process. Sebastian had lack

of confidence in other processing methods

that I implemented, I knew experimenting

with washed Ethiopia and dry Burundi

processes might turn into something not

worthy, it may or may not ruin all the hard

work I had put into those experiments, but

there was no turning back, I refused to give

up and always thought positively.

December 4, 2014 was my last har-

vest which I called mission completed. The

next step was finishing with drying the rest

of coffee by each processing method, but I wanted to add a high quality level we had so far and give them enough rest-

accomplishing this solo was much harder to the coffee of Puerto Rico and make ing time before hulling. I was nervous and

than I thought. Essentially, what I was doing it recognized and respected around the excited at the same time. Below is a walk

at Hacienda Pomarrosa was not what they world. My next step was adding some great through of that process.

were used to. I was trying to change their dimensions to the coffee. Unfortunately, the The Ethiopia washed process began

perspective which was very challenging. results of their previous years crop were not with a primary fermentation of 48 hours,

The first thing I did when I arrived promising due to improper processing and adding a bit of water to cover the surface of

at the farm was to remove defects from sorting. I dedicated my processing methods the beans. Every 12 hours the beans were

green beans from the previous years crop. I and vouched that those who never tried or washed thoroughly with clean water, and

finally cupped and brewed the coffee using tasted coffee from Puerto Rico would be clean water added. After that I had a second-

Chemex, and the result was outstanding. pleasantly surprised. ary under water fermentation for another 48

That coffee, and it was the first and last one After the selection at the sorting hours, instead of 24, where water was filled

that tasted better - others did not get near to table, cherries will be pushed manually to all the way to the top of the tank, allowing

perfection, changed my mind of what could a pipe where the coffee travels by water beans to stay in clean water after initial

be done in local farms to improve quality and it arrives in the de-pulper where a mucilage was removed in the first stage

in spite of hardship, to create something machine removes the skin of the cherries. of fermentation. This process was aimed

unique and attractive, rather than boring. It The green beans will travel to the drying to highlight some acidity and after double

had a medium body, with a velvety feel, very room and soaked in water overnight. Then fermentation the coffee beans were washed

warm and lovely, but challenging, by taking the coffee is put in a mechanical silo dryer, by hand. This was before being moved to

all your senses to find hidden treasures of and dries with an indirect flame for 24 or the mechanical dryer. After drying, when

this island coffee. It had very mild acidity 36 hours. After the drying phase the coffee the targeted moisture level reached between

with notes of prunes, milk chocolate, and is covered with parchment and goes to the 10-12%, beans were moved to warehouse

dark raisins. storage facility. When the beans are ready to rest in parchment.

45