Page 75 - #52 English

P. 75

At that time, Japan only consumed 100,000 coffee

bags a year, but now it imports over 7 million bags. He said he

would like to see Chinese consumers focusing on coffee quality

like they focus on wine quality. China is the largest importer of

high-quality wine. He thinks the Chinese are quite demanding

for wine, and he would like them to keep this attitude for coffee.

Roberto emphasized that Chinese consumers take

quality as the most important thing. That’s why the FNC has

chosen China as the most important coming market.

Pioneer of instant coffee quality and quantity

To know further about the FNC, we must start with

th

the most consumed product, instant coffee. On January 27 ,

we visited Buencafé, which is the largest instant coffee factory

processing Arabica coffee.

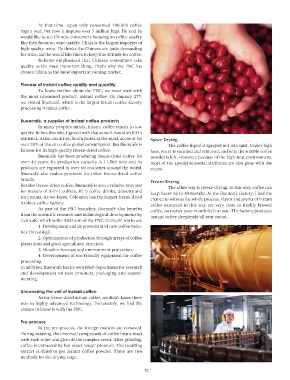

Buencafé, a supplier of instant coffee products

In many people’s minds, instant coffee equals to low

quality. Before this trip, I agreed with that as well. Based on ICO’s

statistics, Asian countries, South Korea as the most, account for Spray-Drying

over 20% of instant coffee global consumption. But Buencafé is The coffee liquid is sprayed out into mist. Under high

famous for its high-quality freeze-dried coffee. heat, water is steamed and removed, and only the soluble coffee

Buencafé has been producing freeze-dried coffee for powder is left. However, because of the high-heat environment,

over 42 years. Its production capacity is 11,500 tons and its most of the special sensorial attributes are also gone with the

products are exported to over 60 countries around the world. steam.

Buencafé also makes products for other freeze-dried coffee

brands. Freeze-Drying

Besides freeze-dried coffee, Buencafé is also a reliable provider The other way is freeze-drying. In this way, coffee can

for makers of 3-in-1 coffees, RTD coffee drinks, desserts and keep flavor up to 30 months. At the Buencafé factory, I had the

ice creams. As we know, Colombia has the largest freeze-dried chance to witness the whole process. Flavor and aroma of instant

Arabica coffee factory. coffee extracted in this way are very close to freshly brewed

As part of the FNC branches, Buencafé also benefits coffee, no matter your mouth feel or taste. The factory produces

from the scientific research and technological developments by instant coffee sleeplessly all year round.

Cenicafé, which is the R&D arm of the FNC. Cenicafé works on:

1. Development and improvement of new coffee varie-

ties (breeding).

2. Optimization of production through arrays of coffee

plantations and good agricultural practices.

3. Weather forecast and environment protection.

4. Development of eco-friendly equipment for coffee

processing.

In addition, Buencafé has its own R&D department for research

and development on new products, packaging and experi-

menting.

Uncovering the veil of instant coffee

As for freeze-dried instant coffee, we didn’t know there

was so highly advanced technology. Fortunately, we had the

chance to know it with the FNC.

Pre-process

In the pre-process, the foreign matters are removed.

During roasting, the chemical compounds of coffee beans react

with each other and give off the complex scent. After grinding,

coffee is extracted by hot water under pressure. The resulting

extract is dried to get instant coffee powder. There are two

methods for the drying stage.

73