June 29(Global Coffee Report) – WMF Professional Coffee Machines debuts the WMF espresso NEXT semi-automatic coffee machine, designed to take automated operations to the next level.

For some years now, high rates of staff turnover and shortages have been an issue in the hospitality sector, one COVID-19 has exacerbated.

Geoffroy Rupprecht, Vice President of Strategic Marketing at GBU Professional Coffee Machines, says the new WMF espresso NEXT coffee machine has been designed to cater to such staffing challenges, while meeting demand for coffee quality and beverage variety.

“Nowadays, machines must guarantee high process reliability and be as easy to operate as possible. This applies to self-service concepts as well as to machines operated by service staff. The WMF espresso NEXT helps to ensure high coffee quality despite changing staff,” Rupprecht says.

To WMF Professional Coffee Machines, its portafilter design has always guaranteed high-quality coffee with maximum process reliability, while the machines themselves underscore the traditional flair of Italian coffee culture. Its new semi-automatic coffee machine delivers on this promise.

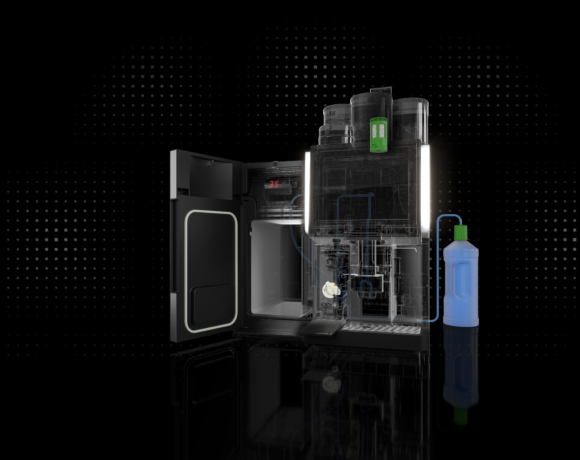

“Bridging the gap between two different worlds, the WMF espresso NEXT combines the benefits and emotionality of a traditional portafilter with the advantages of a fully automatic coffee machine. It looks and sounds like a classic portafilter machine, but the trickier parts of the process are fully automated,” Rupprecht says.

“Recommended for venues with an average daily requirement of 300 cups, it lets you prepare genuine espresso coffee and froth milk in just a few simple moves.”

Rupprecht says thanks to the portafilter’s new, lean, handle shape, it can be inserted even more easily into the group head at the beginning of the brewing process.

“When the desired beverage has been selected, the machine locks the portafilter until the finished product is in the cup. A complementary communication LED strip on the edge of the machine display also indicates that the machine is in production mode,” he says.

“[The machine has] automatic portafilter recognition. Depending on the use of the respective portafilter (single or double spout), the corresponding beverages are shown on the display.”

The operating concept of the WMF espresso NEXT has also been redesigned. Each brewing group now has a separate display screen, with distinctive areas for coffee and milk preparation. According to Rupprecht, the inner workings of the WMF espresso NEXT allows time- consuming and error-prone tasks to be performed automatically, such as the grinding and tamping of beans or foaming of milk.

“The two integrated grinders of WMF espresso NEXT are equipped with precision-honed grinder disks to allow very fine grinding, ensuring a quality espresso. Coffee grounds are delivered directly into the brewer via a closed internal channel, eliminating any waste,” he says.

“The machine automatically doses the correct amount of coffee directly into the portafilter. The coffee is then tamped automatically with the ideal pressure and 100 per cent consistency, so quality does not depend on the skill of the user.”

Fitted as standard, the WMF espresso NEXT also includes the intelligent Dynamic Coffee Assist technology that continuously monitors ground coffee quantity and grinding degree, automatically adjusting to the ideal extraction time for quality espresso.

“Manual fine-tuning is no longer necessary. This streamlines the entire coffee preparation process, permitting time for other tasks such as customer contact,” says Rupprecht.

The machine includes new functions such as Auto Milk Dispensing, which provides increased milk texturing technology from previous models.

“At the touch of a button, the system draws just the right quantity of milk and foams it to the desired consistency. This avoids extra milk and waste, since only the exact amount is dispensed that is actually needed. An americano function as also been added, allowing preparation of the popular beverage to accelerate workflow,” Rupprecht says.

He adds that the WMF Auto Steam provides an additional performance boost.

“This advanced procedure allows simultaneous use of the two configurable, automatic steam lances on the two sides of the machine. In this way, baristas can process two [pitchers] with different milk types or milk alternatives at the same time – doubling machine output,” Rupprecht says.

“What’s more, is that each steam lance can access up to six stored foam profiles, allowing milk foam and plant-based offerings to be foamed and prepared to the desired consistency. The operator can also choose to foam milk manually with the second basic steam wand, allowing an experienced operator to create latte art in traditional barista style.”

To ensure cleaning of the equipment is done routinely, the WMF espresso NEXT is equipped with an efficient cleaning system, eliminating the need for manual cleaning of the coffee system.

The new machine is also equipped with the digital solution platform WMF CoffeeConnect to analyse and process data about the machine, enabling the user to optimise processes, reduce service costs, and boost sales.

“WMF CoffeeConnect provides you with the option to collect valuable machine data. Wherever you are, you can obtain an overview of your sales figures and current service information at any time. You will receive warnings which will let you know if you are running low on beans or if maintenance is required,” says Rupprecht.

“Thanks to the system’s bidirectional design, you can also send tailored promotional offers from your desk directly to the display of a selected machine. The basic functions are available to you free of charge.”

To compliment the machine’s bidirectional design, the modern design of the WMF espresso NEXT unites conventional features with lightweight surfaces and shapes.

“The unusual position of the machine feet lends the portafilter a floating effect, while the brewing groups set special design accents with their eye-catching style. Subtle lighting elements on the rear side of the machine create a sophisticated ambience,” Rupprecht says.

“Functional aspects also play a key role in the design concept of the machine. Stainless steel elements in the working area mean easy, hygienic cleaning, while the lighting behind the brewing groups ensure a clear view of the working area.”

Rupprecht says as a market leader with the responsibility to drive the coffee machine business, WMF has one mission: reacting to the market changes and seeing what the future brings.

“As always, any future features or machines will be guided by listening to what our customers have to say,” he says.

For more information, visit www.wmf.com

NO COMMENT