Turning coffee waste into valuable resources is nothing new these days. Not only can coffee grounds be transformed into beautiful and eco-friendly cups, but they can also be used to create homemade candles, natural cleaning scrubs, and odor reducers. Moreover, they can be added to soil as a mild fertilizer and soil conditioner. In fact, the uses of coffee ground waste can range from small and simple to grand and innovative.

In the heart of Barcelona, D·Origen Coffee Roasters, a renowned coffee shop, has just unveiled the world’s first 3D-printed furniture made entirely from coffee grounds in its new flagship store. The pioneering achievement is a testament to the company’s commitment to sustainability. LOWPOLY, a Madrid-based company specializing in robotics and large-scale 3D printing, collaborated with D·Origen to create this unique space. They used the groundbreaking LOWIMPACT material, a blend of recycled PLA and coffee grounds, to construct the entire coffee shop area from used coffee grounds.

Why Coffee Waste?

When grabbing a quick cup of coffee on the go, it’s easy to overlook the fate of the used coffee grounds. However, the disposal of these waste materials poses a significant environmental challenge. According to a 2013 research paper published in the Journal of Cleaner Production, spent coffee grounds (SCG) account for a substantial portion of organic waste that ends up in landfills. The world produces approximately 60 million tons of SCG annually, with Australia alone generating around 75,000 tonnes of coffee ground waste each year.

One of the most concerning aspects of food waste is its potential to generate methane gas, which is 21 times more potent than CO2. Additionally, the decomposition process releases other greenhouse gases, such as carbon dioxide, nitrous oxide, and ammonia. With millions of tons of food waste being generated daily, it is crucial that we find solutions to reduce waste sent to landfills and instead turn them into valuable commercial applications. By doing so, not only will we help mitigate the consequences of global warming, but we will also contribute to the economy.

The founder of LOWPOLY and the leader of the D·Origen Coffee Shop project, Gianluca Pugliese, always believed in the power of food waste as a potential element for manufacturing materials. The company has used food waste from oranges, grapes, bananas, and olives in past projects, with coffee grounds being their latest endeavour. “The use of recycled coffee grounds in design carries significant environmental implications,” says Pugliese. “I think it is interesting to try to find a new use for it, thanks to the technology and innovation that we carry forward in LOWPOLY.”

A Coffee Shop Made by Coffee

Michael Uhlig has always held the idea of sustainability in the coffee industry dear to his heart. As the founder of D·Origen Coffee Roasters, when he first opened his coffee shop in Spain, everything was developed around sustainability. The coffee shop itself is a pioneer of serving specialty coffee sourced from their coffee plantation in Panama, working closely with the producers to ensure the high quality of the coffees they brew. The coffee shop has won the best specialty coffee in Spain three times. “In the end, sustainability is not only recyclable products but also fair working conditions and sustainable pricing structures, which we are very sensitive to in regards to coffee production in countries of origin,” said Uhlig.

Of course, the coffee itself is not the only aspect of sustainability in the coffee industry that Uhlig is paying attention to. Today, as D·Origen Coffee Roaster becomes more and more successful, it serves more than 200 wholesale customers and has expanded to three coffee shops, including the new flagship in Barcelona. Uhlig wanted to showcase his vision of sustainability in this new flagship space and what the future of the coffee industry should lead to. He stated: “Being from a smaller town in Spain, we had the necessity to establish a flagship in one of Spain’s main cities to find ourselves one step closer to our customers and grow our brand perception.”

Uhlig envisioned a flagship coffee shop where every element would be sustainable, from the furniture to the very fabric of the space. In line with this vision, he sought to create something from waste that could be used in the new shop. He believes that every small step counts to achieve sustainability in the coffee industry. After searching for a few differentiating designs based on sustainability, he eventually came across LOWPOLY. LOWPOLY is a Madrid-based company dedicated to robotics and large-scale 3D printing to convert waste into products established in 2018.

Gianluca Pugliese is the founder and director of LOWPOLY, who is dedicated to design as a way to solve problems. He has been appointed Ambassador of Italian Design in Spain and is among the pioneers of 3D printing in Europe. The company has previously collaborated with Adidas, Armani, LVMH, and many others on innovative and sustainable projects. “Their flexibility and proactivity quickly turned into a great relationship, allowing us to find the inspiration for the final design you can find in our coffee shop in Barcelona,” Uhlig said in the interview.

Through a common friend, the two companies that share the same vision soon decided to work together to deliver the 3D printed coffee furniture project for D· Origen’s new flagship space. In fact, LOWPOLY formulated the construction material from coffee waste in 2014 and has already used it for some minor projects. However, they didn’t have the opportunity to showcase their innovative concept grandly. Pugliese reflected: “It took years before meeting a client like D·Origen who married our idea and vision, presenting us with an important space like the one in Barcelona.”

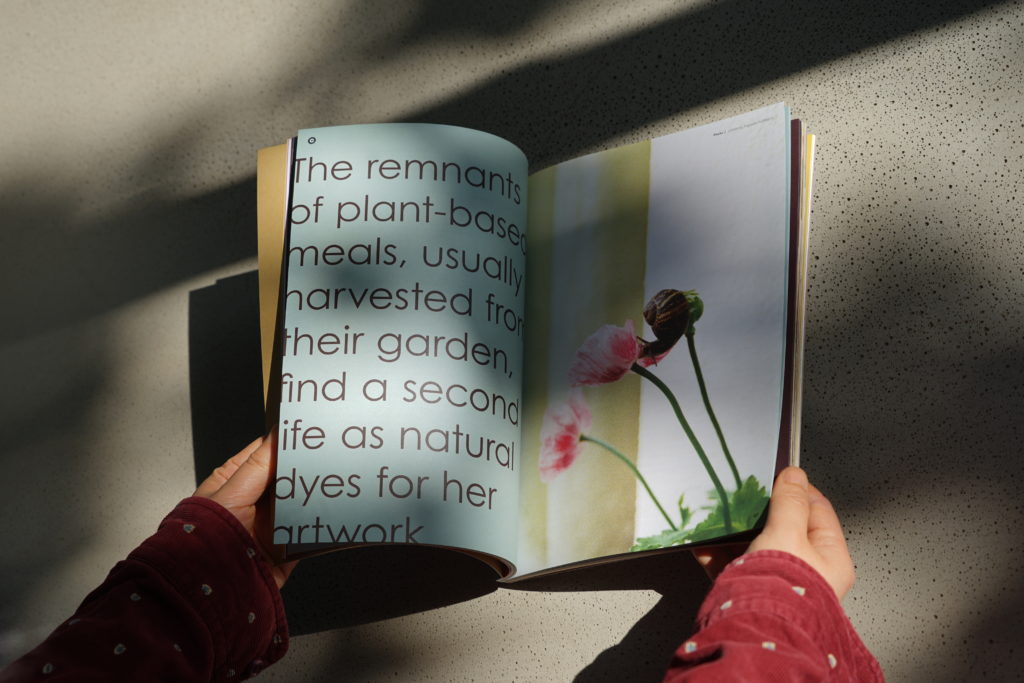

Many of the custom furniture in the new flagship space, including the counters, lamps, and stools, are all crafted with special “coffee grounds” materials. And all these coffee ground comes from D·Origen. The team from LOWPOLY collected the coffee grounds from D· Origen’s other two coffee shops, treated them, and converted them into material for 3D printing. They then made the waste into a new construction material named LOWIMPACT®, a master batch made from recycled PLA and coffee grounds. This biodegradable, petroleum-free material contains 98% organic content and can be combined with various polymers to achieve different color tones.

Nevertheless, making this innovative material takes work. Organic waste is complicated to manage. It has very fast treatment times, contains a lot of humidity, and can generate mold. The LOWPOLY team developed a system to solve these problems quickly. Then, the material is put into large-format 3D printers with modified extruders capable of handling materials with high organic content. The use of industrial robotic arms ensured precision and facilitated the creation of five bespoke pieces.

The overall design of the furniture is much inspired by the place where the cafe is located, Barcelona, home of many of Antoni Gaudí’s signature structures, such as Sagrada Familia, Casa Mila, and Casa Batlló. LOWPOLY led a partnership with designer Arturo Tedeschi, who used artificial intelligence and parametric design to translate taste into an almost synesthetic process, creating an experience that goes beyond the visual by turning these sensations into tangible forms. The shapes of the furniture recall the soft geometries of Gaudí’s artwork. For example, the lamps have beautiful geometrical curves that complete the harmonious design of the space.

The counters are the greatest testament to the core innovation of this project. The architectural vision for the counters was inspired by the fluidity and richness of coffee, translating tactile and gustatory sensations into tangible forms. The unique amber textures of the LOWIMPACT® material, when backlit, create mesmerizing light effects that enhance the counters’ forms, turning imperfections and irregularities into distinctive features and strengths.

The color shades are created naturally by different densities of coffee grounds. Moreover, the huge counter piece could not be completed without cutting-edge 3D printing techniques and equipment. “Projects like D·Origen Coffee demonstrate how SCG can be sustainably repurposed, transforming waste into innovative materials for design and construction.” Said Pugliese. The whole project reflects an innovative production that combines atheistic and high technology. Moreover, it set a new standard for sustainability in the world of specialty coffee.

A Look to the Future

As Pugliese told us in the interview, there are various advantages of construction materials made from coffee grounds. The first and the most important one is obviously being able to use waste and transform it into a new product. Pugliese said, ” Using our innovative LOWIMPACT® material, we implement 25% less plastic. Moreover, since we used bioplastic, this furniture would be compostable.”

As the project with D·Origen’s new coffee shop proves highly successful, Pugliese and his team plan to continue experimenting with the material over the next few months. During this time, they aim to create various objects for different brands, testing the material’s versatility. In parallel, they are also developing a system to manufacture the material locally, which will enable them to sell it as filament for 3D printing or in pellets for large-format 3D printing. This new system will allow individuals to create objects with multiple functions, unlocking a wide range of possibilities.

LOWPOLY is not the only one who has faith in the material made by coffee grounds. A few companies and institutions around the world have touched on this topic already. Re-Worked, a non-profit industrial design and product manufacturing company from the UK, has produced a few pieces of furniture that are made from coffee waste. The company stated that it has sold 300-400 pieces of coffee-made furniture each year since its launch in 2013.

Google has bought designer furniture from them comprising 60% used coffee grounds. On the other side of the planet in China, the professors and students from the Tongji University College of Design and Innovation have made coffee grounds into dining tables, chairs, and loudspeaker boxes in cooperation with German specialty chemical firm Covestro.

Moreover, many innovative companies and institutions have seen coffee grounds as a very potentially sustainable material. Coffeefrom, an innovative Italian start-up specializing in transforming coffee grounds, has developed thermoplastic materials made from recycled coffee grounds. The material is suitable for injection molding and used to make automotive, tableware, and more. British institution BeaNused®, which mainly focuses on sustainable material solutions, also managed to create coffee grounds made from materials.

Their innovative patent-pending process mixes recycled coffee grounds into various plastics, including bioplastics, renewable and recycled polymers, and ocean waste. These materials can then be shaped and formed into many different products. In fact, research done by Rajeev Roychand at RMIT University in Melbourne found that coffee grounds can replace some of the sand in concrete and make the material stronger because the biochar helps create a porous structure that traps moisture and stops the concrete from drying out from the inside.

“I am sure that innovation and sustainable materials will be very important elements for a good part of the present and future manufacturing. We are at an environmental compromise and we cannot procrastinate. In recent years, we have confirmed this, with big fashion brands trusting us to create shop windows and stores all over the world,” said Pugliese.

In the future, we might see coffee grounds being used in more aspects, creating a circular economy. Talking about sustainability in the coffee industry is easy, but it is difficult to imply it truly. However, people like Pugliese and Uhlig decided to take the hard way and carry out projects showcasing their beliefs. Uhlig said: “At D·Origen, we are aware that sustainability in the coffee industry is only achievable through small but important steps. And that’s the path we are on.” We all know that sustainability will be the future for the coffee world and the universe in general. However, it is now the time to take a step. Perhaps a step into D· Origen’s new flagship space with all furniture made from coffee grounds would help you have a taste of the future.

NO COMMENT