Chris Flechtner

The Designer since the Revolution

Living in Kyoto, Japan, the Industrial Designer of Slayer Espresso, Chris Flechtner loves “ walking down the street and enjoying a Cheese Latte from a great little shop opened with the help of Sawada-san from Tokyo/Chicago”, as he shared. It doesn’t sound much like a treat, but to Flechtner, it is indeed. “When not designing, I am designing; I can’t turn it off, it’s just part of me,” he confessed. “I also enjoy cycling, exploring and eating amazing food.”

Museum-inspired Aesthetics

On a weekly basis, Flechtner wandered around Boston’s Museum of Fine Arts during his Graphic Design studies at the Massachusetts College of Art and Design. If you have the chance to meet him in person, his tattoos would reveal his affection for Eastern culture. He was drawn to the Asian art wing especially, where he marveled at the fine craftsmanship of Japanese samurai swords. According to him, it was this fascination that led him to an apprenticeship with a local bladesmith, building and restoring swords. Still, you might find it hard to connect the guy behind Slayer with this Flechtner at school.

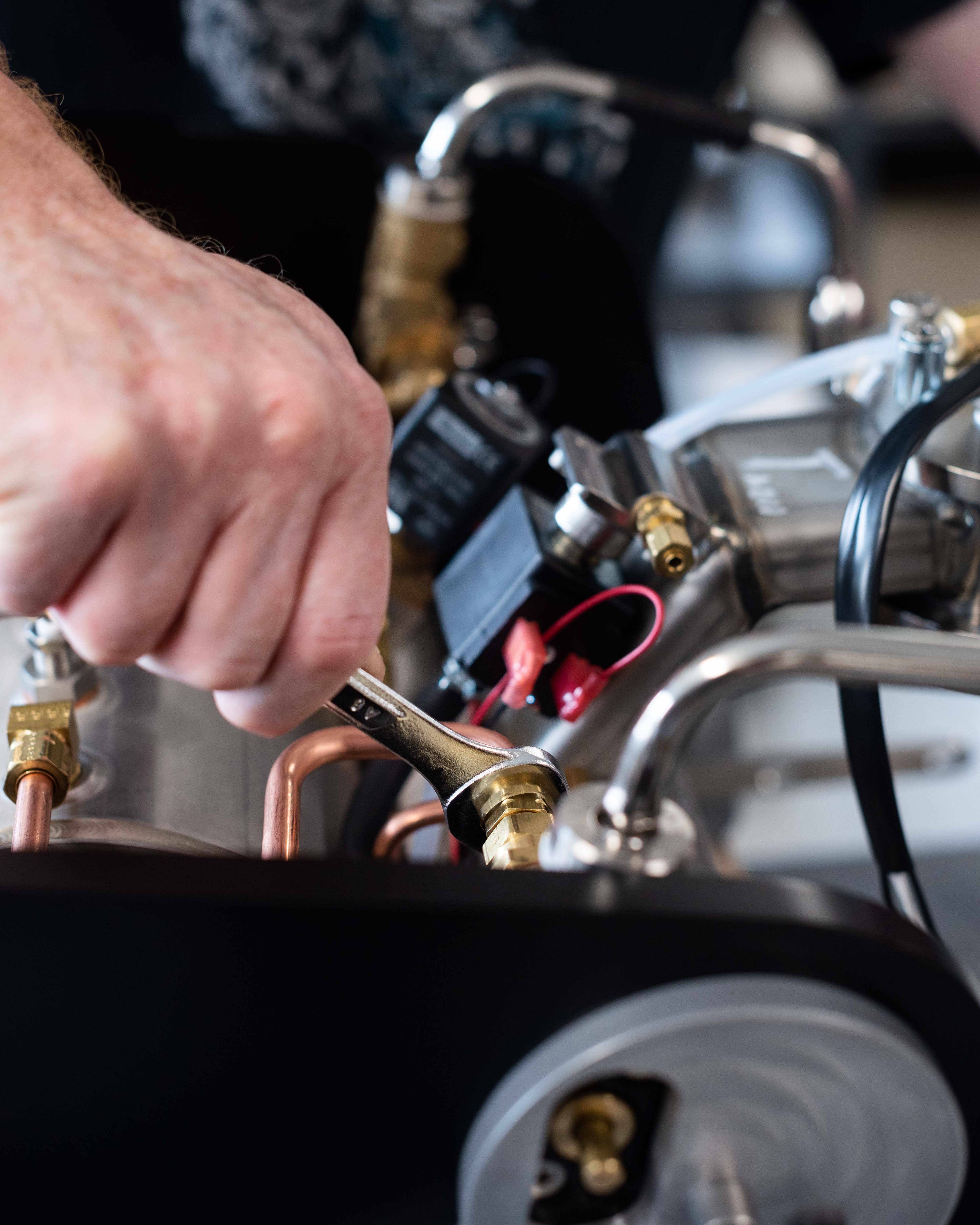

Photo: Slayer Espresso

Flechtner studied jewelry-making and metalsmithing at first and then switched to MassArt’s Fine Metalsmithing program as he was invigorated by the chance to work with his hands. He also earned an MFA in furniture design from the historical Cranbrook Academy of Art. As he graduated, Flechtner worked as a furniture and product designer in the architectural industry. However, with abundant experiences and professional skills in design and arts, he had no barista experience, no family lineage, nor anything else to suggest a bright future in designing espresso machines before joining Slayer Espresso in 2007, the exact year that the brand’s revolutionary products kicked off, provoking innovation in the design of espresso machines in specialty coffee. “To our Founder, Jason Prefontaine, part of the appeal was that Fletchtner came with fresh eyes,” shared Jacob Smit, senior content manager & copywriter with Slayer.

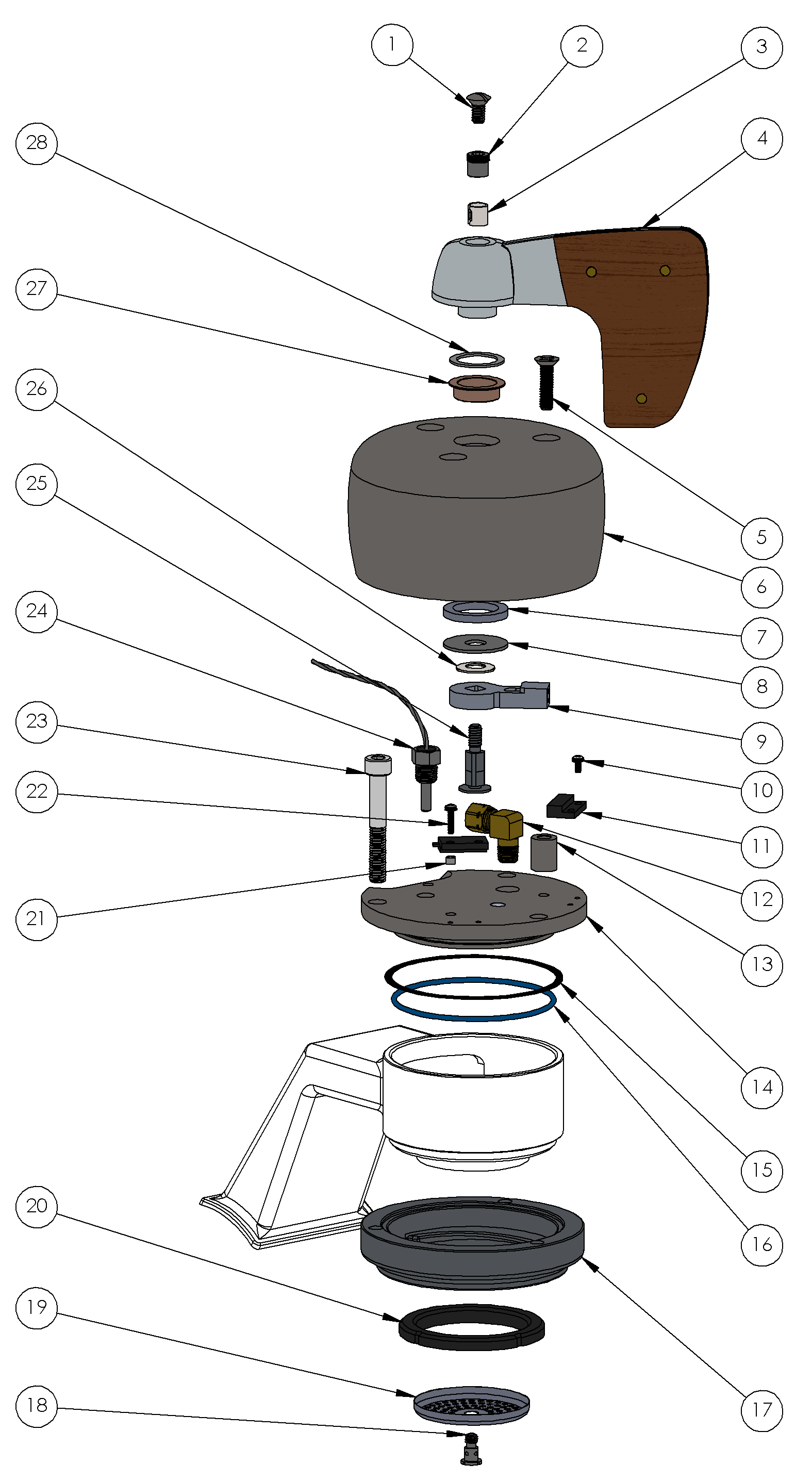

Flechtner’s commitment to add beauty to the world helped him develop a highly utilitarian style with a balance. This could already be seen through his works of furniture, light fixtures, and motorcycles. For now, the selection of natural wood for porta-filters and actuators and sandcasting for X’s on the Slayer machines is a reflection of his thoughts on prizing beauty in transience and imperfection. Those inspiring days at the museum allowed Flechtner to let the Japanese aesthetic of wabi-sabi inform his palette of materials.

Photo: Slayer Espresso

The Fresh Eyes behind Slayer

The design of Slayer espresso machines wows both baristas and consumers. It’s the ability the brand has to react quickly in response to the market demands in high-quality espresso extraction, as well as the courage to take on the challenge in producing something that is truly artwork itself. “Slayer Espresso was created because people in the industry were reluctant to take the risks necessary to see big changes,” shared Flechtner. “It’s our hope that we can inspire our fellow coffee friends to continue pushing the limits of what we already are comfortable with in all of our processes associated with coffee — we want to be the catalyst for change.”

During the innovation and change, Flechtner also encountered challenges. “As an industrial designer, the distinction lies not in aesthetics, but process,” he said. When a ceramic artist designs as they go, it can turn out to be something that is one of a kind, but not easily duplicated. Industrial design is another story. The challenge that Flechtner faces is creating designs that are practical and replicable, “built with consistency for each of the hundreds — and thousands — of machines that we would produce by hand.” He said: “Industrial design has the unique goal of mass production.”

Photo: Slayer Espresso

A hand-made touch of uniqueness and a combination of aesthetics and functionality make Slayer a big name in the coffee world. All of its cafe owners love taking shots with their beautiful espresso machines. The pale pink Slayer at Host Milano 2019 was the apple of people’s eye. “Each piece made with these materials displays eccentricities that make it truly unique. In the case of wood, time only adds to its beauty, as the handles show subtle wear,” shared Flechtner. Also at Host, the Steam Wand X[1] preview cheered many baristas and cafe owners. “This stand-alone steam wand offers the cafe owner/ barista the ability to increase their milk or alternative steaming capacity without adding an additional full size machine,” explained Flechtner.

‘Design’ at Slayer means a machine needs to be both a practical tool and an elegant centerpiece, according to Flechtner. Having him on-board since 2007 has turned Prefontaine’s vision into a reality.

Photo: Slayer Espresso

Improve as I Create

Now, Flechtner runs an independent design office in Kyoto as he designs espresso equipment exclusively for Slayer and Gruppo Cimbali[2]. The passion for design and constant quest to improve what he has created means he is always focused on what’s coming next. “I think my favorite model of Slayer is the one in my head that I have not yet designed.”

With appreciation for antique hand tools used for hand-brewed coffee and tea, Flechtner is happy to be embraced by the rich cultural history and eye-opening rituals, beautiful yet inspiring, in Japan. “Even our six-year-old son is learning the tea ceremony in school now,” he said.

Photo: Amelia Hallsworth

Although surrounded by great coffee and espresso bars in Kyoto, he confessed: “I am not as much of a coffee snob as I probably should be.” Instead, he enjoys making coffee with his Bialetti Moka Pot at home and in the office, as well as “a local Japanese brand of coffee from an old-time producer”.

Next time, you walk past a coffee shop and spot a Slayer, you may stop to take a closer look at the machine.

Notes:

[1] The Steam Wand X is in the final phase of development, it is not yet for purchase but is ready for volume stress testing and customer facing engagements that help the brand gather consumer opinions.

[2] Gruppo Cimbali and Slayer joined hands in partnership in 2017, which also assists Slayer in streamlining its manufacturing process through consultation and lean production implementation, enhance its engineering expertise and provide access to build a large, high-quality team to truly achieve all of Slayer’s goals.

Chris Flechtner

Chris Flechtner

With an academic background in graphic design, jewelry-making, and metalsmithing, Flechtner earned an MFA from renowned Cranbrook Academy of Art where he studied furniture design. He has been the Industrial Designer for Slayer since 2007, and now has an independent design office in Kyoto, Japan.

NO COMMENT